Dry Can Belts Dry Can Belts

|

| |

Timing Belts Timing Belts

|

|

|

Key Features Key Features

Fiberglass tensile cord provides high strength, excellent flex life, and high resistance to elongation. Neoprene body provides protection against grime, grease, oil and moisture. Nylon tooth facing provides a durable wear surface for long service life. Eliminates lubrication and re-tensioning to reduce maintenanceand labor required on drives.

Also Available in Section : MXL, XL, L, H, XH, XXH |

Applications Applications

PowerGrip® Timing Belts are suitable for office machines, machine postage equipment, sewing machines, vending machines, outdoor power equipment, agriculture,food processing, HVAC, oil, wood, paper, sand and gravel. |

|

|

| |

| |

Power Grip®GT®2 belt Power Grip®GT®2 belt

|

| |

|

|

Key Features Key Features

Fiberglass tensile cord provides high strength, excellent flex life, and high resistance to elongation

|

Neoprene body provides protection against grime, grease, oil. and moisture. Nylon tooth facing provides a durable wear surface for long service life. Gates' patented tooth profile is designed for use with a specific sprocket groove profile. The sprocket groove-belt tooth combination increases capacity, while improving registration. PowerGrip® GT2® greatly exceeds HTD® in tooth ratchet resistance. Eliminates lubrication and re-tensioning to reduce maintenance and labor as compared to roller chain drives. |

| |

|

Power Grip® GT W2 belt / sprocket combinations match or exceed the positional accuracy of PowerGrip ® Timing belt/pulley systems. Also Available in Section : 2 MR, 3 MR, 5 MR |

| |

|

Applications |

PowerGrip GT belts are suitable for many applications including data storage, machine tool, hand power tools, postage handling, DC Stepper/Servo, food processors, office machines, centrifuges, money handling, medical diagnostic, sewing machines, ticket dispensers, robotics, vending machines, and vacuum cleaners. |

|

| |

|

| |

| |

|

|

| |

| |

Polyflex® JB ® belts Polyflex® JB ® belts |

|

|

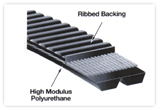

Key Features Key Features

High Modulus Polyurethane compound resists fatigue, wear, ozone, and most environmental conditions. Precise casting method eliminates layers and overlaps for smooth running and low vibration.Ribbed backing provides greater lateral stability and relieves bending stress. Working temperature range: - 65T to +180°F (-54°C to +85°C). Joined belt construction provides high stability, preventing belts from turning over or coming off of the drive.

Also Available in Section : 3 MJB, 5 MJB, 7 MJB, 11 MJB |

Applications Applications

Use in place of Polyflex® singles on drives requiring joined sets. A partial feting of applications include machine tools, computer peripherals, medical equipment, library equipment, small appliances, blower drives and dough mixer. |

|

| |

Polyflex® belts Polyflex® belts |

|

|

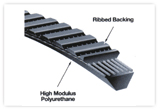

Key Features Key Features

High Modulus Polyurethane compound resists fatigue, wear, ozone,and most environmental conditions. Precise casting method eliminates layers and overlaps for smooth running and low vibration. Ribbed backing provides greater lateral stability and relieves bending stress. Working temperature range: -65° F to +180° F (-54° C to +85° C)

Also Available in Section : 3M, 5M, 7M, 11M |

Applications Applications

A partial listing of applications include machine tools, computer peripherals, medical equipment, library equipment, small appliances, blower drives and woodworking machines. |

|

| |

| |

| |

|

| |

| |

| |

Variable Speed Belts |

|

|

|

|

Key Features Key Features

Notch Design reduces thermal and bending stresses for longer life. Smooth Running construction for minimal vibration at high speeds. Meets RMA oil and heat resistant standards. |

|

Applications Applications

Suitable for all industrial, wide-speed range open pulley or enclosed device variable speed drives. |

|

|

|

|

|

|